One-Stop Electronic Manufacturing Service

From PCBA to Final Product

✅ End-to-End Electronic Manufacturing

✅ Prototype to Production Support

✅ Integrated Manufacturing & Quality Control

Welcome to CINDY Mould, your trusted partner for end-to-end electronic manufacturing solutions.

We specialize in customized electronic products and services.

From Enclosure design, PCB assembly and testing to final product assembly ,packaging, and global delivery,

We provide one-stop solutions that bring your ideas to life with speed, quality, and reliability.

Who we are ?

CINDY Mould Industrial LTD

As a subsidiary of JIN YI Moulding, established in 2014, we specialize in injection molding, PCBA processing, and complete product assembly. With advanced equipment and full-process capabilities — from design and prototyping to mass production and global delivery — we simplify supply chains and accelerate time-to-market. Trusted by global brands, we provide reliable, high-quality solutions across consumer electronics, smart devices, automotive, and industrial applications. →learn more…

JIN YI Moulding Product Co., Ltd.

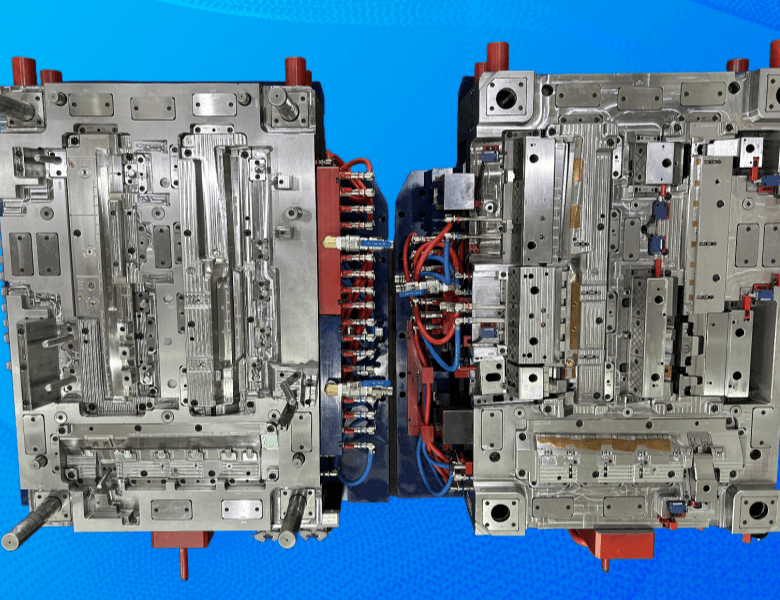

Founded in 1998 in Dongguan, JIN YI Moulding specializes in injection mold making, molding, and product assembly. With a 30,000 m² production base, advanced CNC, CMM, and other machining equipment, and injection machines ranging from 80 to 1600 tons — including a new facility in Maoming since 2022 — provide CINDY Mould with strong technical support and high-quality injection housings.

From Design to Delivery

Customized smart manufacturing for your future

One-Stop Manufacturing

High-quality solutions trusted globally

Technology-Driven Innovation

Turning ideas into reality through advanced manufacturing

Our Capabilities

We provide end-to-end manufacturing solutions.

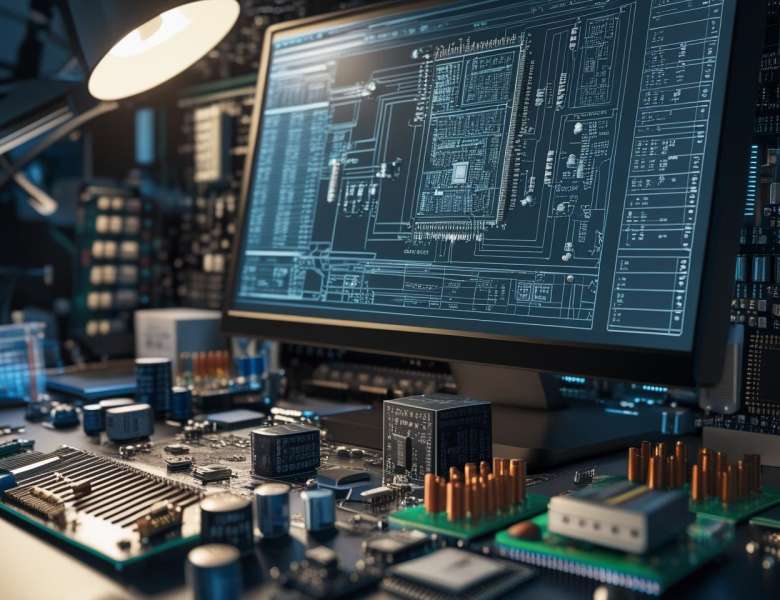

Product Design & Engineering

From industrial design to DFM analysis and mold flow simulation, we support product development with innovative and practical solutions.

Injection Molding & Tooling

Advanced CNC, CMM, EDM, and injection machines (80–1600 tons) ensure precise, high-quality plastic components.

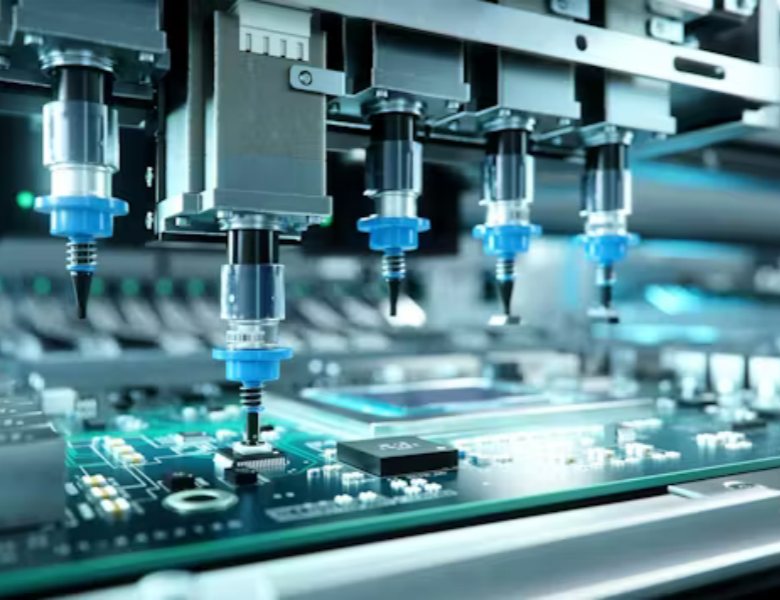

PCBA & Assembly

Automated SMT and plug-in lines, with AOI inspection, guarantee reliable and consistent electronic assemblies.

Quality Testing & Validation

Comprehensive testing, including functional, reliability, and environmental assessments, ensures compliance with international standards.

Final Product Assembly

Standardized assembly lines and functional testing processes ensure complete, ready-to-ship products.

Custom Packaging & Global Delivery

Flexible packaging solutions and international logistics enable safe, on-time delivery to clients worldwide.

Capacity & Tech Highlights

Industries We Serve

We provide end-to-end manufacturing solutions across multiple industries, delivering high-quality electronic products.

Smart Home

PCBA, assembly, and complete smart home product manufacturing.

Consumer Electronics

End-to-end production of electronic gadgets and accessories.

Medical Devices

High-precision manufacturing for medical electronics and devices.

Automotive

Custom PCB and assembly for automotive electronics.

Industrial & IoT

-1024x768.jpg)

Reliable electronic solutions for industrial IoT applications.

Drones & SOS Devices

From PCB assembly to full product integration and delivery.

Why Choose Us ?

1️⃣ Technology-Driven · Innovation-Led

We focus on smart home, IoT, security, and consumer electronics, turning ideas into high-quality products.

2️⃣ End-to-End Solutions

From product design, rapid prototyping, tooling, PCBA assembly to global delivery, we provide full-cycle services for fast market launch.

3️⃣ Strong Capacity · Complete Facilities

Our facilities cover tooling, injection molding, electronics, full product assembly, and packaging, with an annual output exceeding 20 million units.

4️⃣ Automated Quality Assurance

Advanced SMT, plug-in lines, AOI inspection, and MES smart management ensure consistent, high-reliability PCBs and finished products.

5️⃣ R&D Expertise · Empowering Every Step

Professional design and engineering teams proficient in structural, electronic, embedded, and packaging design, supporting projects from concept to production.

6️⃣ Strict Quality Control

Independent quality center conducts functional, aging, environmental, and compliance testing, with a one-year warranty for peace of mind.

7️⃣ International Certifications · Trusted Worldwide

ETL, CE, GS, FCC, CCC certified, serving clients across Europe, the Americas, Asia, Australia, and more.

8️⃣ Customer Success · Sustainable Growth

Customer-centric approach combined with smart manufacturing and global delivery, consistently providing innovative and efficient custom solutions.

FAQ

What services does Cindy Mould provide?

We offer complete manufacturing solutions, including product design, mold making, plastic injection molding, PCBA, final assembly, packaging, and global delivery.

Can you support both prototypes and mass production?

Yes. We provide fast prototyping with no MOQ, as well as high-volume production to meet your project needs.

What industries do you serve?

We work with customers from automotive, consumer electronics, home appliances, IoT devices, and industrial products.

How do you ensure product quality?

We use advanced inspection equipment such as CMM, AOI, and functional testing, and follow international standards (ETL, CE, FCC, CCC) to guarantee consistent quality.

What is your production capacity?

Our injection molding machines (80–1600 tons), SMT lines, and multiple assembly lines enable us to deliver large-scale production efficiently.

Can you provide product design support?

Yes. We offer structural design, DFM analysis, and electronic hardware development to help clients bring their ideas to life.

How do you handle packaging and delivery?

We provide custom packaging solutions and coordinate global logistics to ensure safe and timely delivery.

How can I start a project with Cindy Mould?

imply contact us via email or the website form with your requirements. Our team will review your project and provide a tailored quotation and solution.

How We Work ?

Ready to bring your ideas to life?

CINDY Mould is not just an efficient manufacturing company .

We are a responsible, forward-thinking, and customer-focused smart manufacturing partner.

Fill out the form below or reach us directly at sales@cindy-mould.com

Let’s create high-quality products together.

CINDY Mould — your trusted one-stop smart manufacturing partner worldwide.